We always recommend that this be installed by a professional gunsmith.

What you want to achieve is a rifle that functions correctly with the proper amount of gas pressure.

This is done by adjusting the amount of gas into the system. When this is done it should be with the actual load you plan on shooting. Too little pressure going through the system and the rifle will not be reliable and too much will cause excessive recoil and could damage your rifle.

Official Installation Guide

Review & Install with SGT of ARMS

The adjustments must be done in a safe area following all safety rules. “Make sure that the firearms if completely unloaded”

- We are assuming that you have the gas block installed, properly aligned with the barrel gas port and the gas tube properly installed with the gas block tightened in place.

- Once this is done loosen the front set screw, then turn the adjustment screw on the side in until the screw stops (no not over tighten). This will restrict the gas to going to the gas tube all the way down.

- What you want to do now is shoot the rifle at a safe location in a safe direction with 1 round in the magazine.The round should fire and not lock the bolt back. This is because there is not enough gas to properly extract, eject and lock the bolt back.

- Now turn the adjustment screw 1 full turn out. Fire the rifle again with 1 round in the magazine. Continue this until the bolt locks open. Once it locks back this is the point where you have enough pressure to function the rifle.

- Now back the adjustment screw out 1/2 turn more, then tighten the front set screw. This will lock the adjustment screw in place.

- Now test the rifle with 10 rounds making sure it ejects and functions correctly and locks the bolt when empty.

You may be done now or you may need to allow a little more pressure. If you do adjust do so at ½ turn increments. Remember to loosen the front set screw first and re-tighten after.

We always recommend that this be installed by a professional gunsmith.

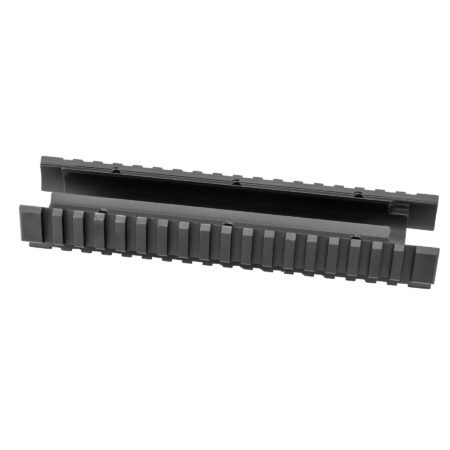

- CNC machined 4140 chromoly steel

- Gas adjustment will not shift once the adjustment screws are set and locked in place

- Nitride/Melonite QPQ finish

- Chamfered edge, semi-press fit

- USA made steel & Machined in the USA

- Weighs 2oz

- Fits under most free float handguards

- Internal Diameter 0.750

- Same profile/height as the standard low-profile gas block

- Includes (2) set screws for a secure attachment

- Includes a 5/64″ Set-Screw and a 5/64″ Retaining Screw (Rearward facing)

- Accepts standard gas tube roll-pins but, a roll-pin is NOT included.

- Clamp set screws are 3/32″.

Grips

Grips

Reviews

There are no reviews yet.